The Bottom Line: 304 Stainless steel is superior to 430 Stainless. No stainless is completely rust-proof, but there are certain grades of stainless that are better suited to the high-heat and elements that pellet grills are subjected to. Carbon Steel is useful in non-exposed areas, but is extremely prone to rust.

Carbon Steel in Grills

Let’s start with the basics by explaining carbon steel, the single most common material used in the manufacture of pellet grills today. Basically, carbon steel is raw steel that has had carbon added to it in order to make it stiffer and stronger. This is why you often see carbon steel in knives. Strength and stiffness means that it’s easier to create a fine edge on a knife, and one that will last. The best knives, therefore, are made from steel with a higher carbon content. For grill manufacturing, however, carbon is used for strength: so that a grill grate doesn’t sag, or a bolt doesn’t round when tightened. Carbon steel is stronger and more durable than stainless steel.

Unfortunately, all normal steel, carbon steel included, is highly susceptible to rust and corrosion. Steel will rust, period. Even moisture vapor in the air will begin the process. It is, however, a much more inexpensive material to use than stainless steel, so many non-exposed parts in a grill are made of carbon steel. Manufacturers may coat their steel–in powder coating or porcelain, for instance–to try and protect exposed metal. But even coatings can chip, be ground away (think about steel brushes on your grill grates) and then begin to rust.

Stainless steel is far more preferable to carbon steel as a grill material, especially in parts exposed to the outdoor elements. But the insides are also subject to abuse: moisture from meat being evaporated, fatty acids and smoke attacking the metal, abrasive cleaning. So, if you can afford to, always get the grill with the most stainless steel that you possibly can. It will make a difference in the life of your grill.

All stainless steel isn’t the same, however, and that is the reason for this deep-dive into steel manufacturing materials. You need to know the what and the why behind the metals used in your pellet grills.

Stainless Steel: An Overview

It’s worth repeating here: All stainless steel isn’t the same. And all stainless steel isn’t totally stain- and rust-free, nor is it bomb-proof. To understand the different types of stainless being used today in pellet grills, it’s important to first understand what makes up these various types.

Stainless steel isn’t a single alloy. It is a combination of various metals combined to produce a product with a specific set of benefits. There are almost endless varieties of stainless steel being used in manufacturing today. Each type and grade has its specific characteristics and specific uses, based on its ingredients and properties.

For our explanation, we’ll focus on three characteristics of stainless steel that cause them to perform differently in grills, and then on the two primary grades of stainless steel currently in use: 304 and 430.

Family vs Grade vs Gauge: The 3 Things to Look For

Stainless has three main things to look for, often found on material labeling for it, but sometimes not specified by grill manufacturers:

- Family

- Grade

- Gauge

The combination of family and grade are usually sufficient to understand the makeup and advantages of a specific stainless steel alloy. They each have their advantages and their general uses in the world. Gauge is quite simply a measurement of the thickness of a particular type of stainless steel.

Stainless Steel Families: Which Are Used in Pellet Grills?

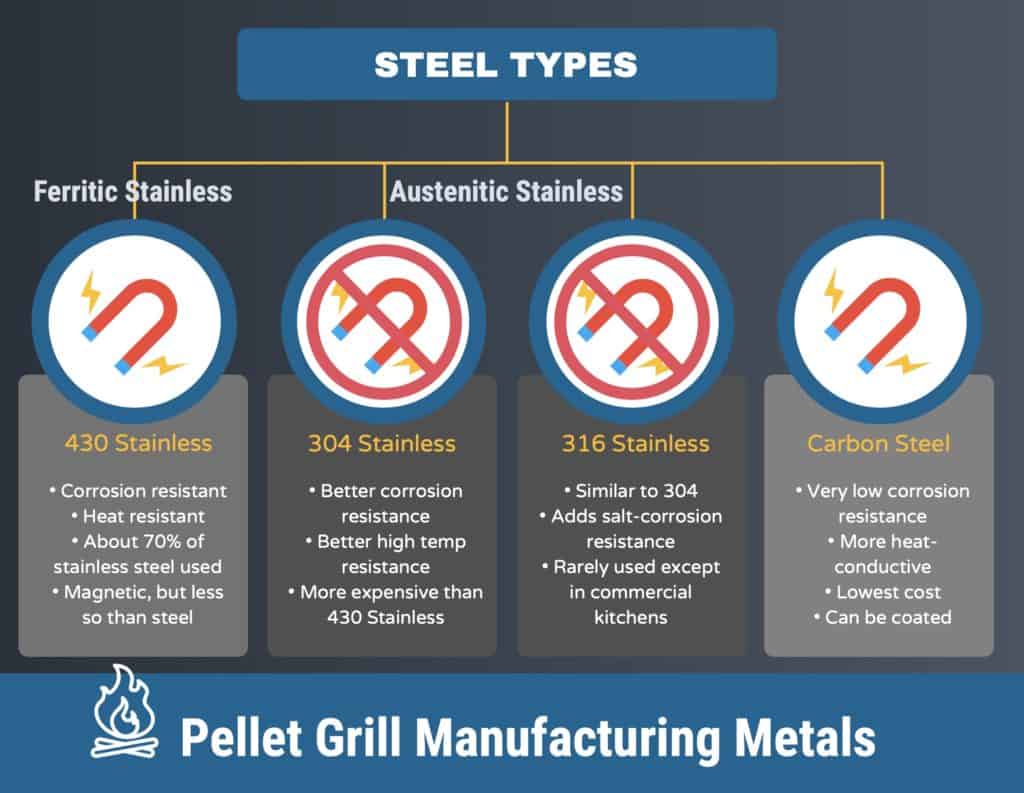

The Family in Stainless Steel Alloys refers to the overall properties of the alloy and are categorized based on the ratio of metals in the alloy. Below, you’ll see the main Families (sometimes called Alloy Groups) that are used in grills, Ferritic Stainless and Austentic Stainless.

More Stainless Means Less Worry

Ferritic Stainless Steel Family: Lower Cost, Some Resistance

Ferritic Stainless grades add Chromium to regular steel to create the alloy. Other elements are also added, but Chromium is the main added ingredient. They are resistant to corrosion and oxidation compared to carbon steel while remaining resistant to stress and cracking. Because of the alloy’s atomic structure, ferritic grades are magnetic (more about magnetism later.) While they are corrosion (rust) resistant, they are inferior to austenitic grades. This is because they don’t contain Nickel in the alloy, which has some advantages. Ferritic grades are often used for sinks, decorative trim, and automotive applications, as well as in many gas grills and pellet smokers. While superior to carbon steel for corrosion resistance, they are generally less expensive than austenitic grades and so manufacturers use them to save production costs.

Austenitic Stainless Steel Family: Higher Durability, Higher Cost

Austenitic stainless is less common in pellet grills, but far more common in environments like commercial kitchens and industrial laboratories. This is because it has superior corrosion resistance and mechanical properties compared to ferritic grades, though at a higher cost. Stainless in this family has a higher Chromium content and adds Nickel to the alloy. None of the grades in this family are magnetic, usually. (More on magnetism later.) There are two categories within this family:

- Low Carbon Grades (L Grades)

- High Carbon Grades (H Grades)

The High Carbon Grade steel sometimes used in food appliances such as outdoor kitchens and high-end grills have a minimum of .04% Carbon and a maximum of .10% Carbon. This higher Carbon helps to keep strength in the steel at extreme temperatures. As well, the Nickel in the alloy lends it an extremely shiny appearance–almost mirror-like–and is generally a little easier to maintain and definitely looks better.

Stainless steel from the Austenitic family is used extensively in processing equipment in commercial laboratories, and in the food, dairy and beverage industries. They are more expensive to use in manufacturing, but possess excellent strength, corrosion resistance and extreme temperature resistance.

Other Families

There are two more families of stainless, but we won’t cover them here as they aren’t used by grill manufacturers. They add additional elements to the alloy like titanium or copper for specific uses like industrial pollution, petroleum, or seawater environments:

- Duplex (Ferritic-Austenitic) Stainless Steels

- Precipitation-Hardening (PH) Stainless Steels

Grades of Stainless Used in Pellet Grills: 304 vs. 430

There are literally dozens of grades of stainless steel used in manufacturing for both commercial and industrial uses. We are going to focus on the two main grades in use (and one other that is much more rare,) and highlight the main differences between them.

430 Grade Stainless

The most common type of stainless used in pellet grills, 430 Grade is also the least expensive to use. It is a basic grade from the Ferritic family and is therefore magnetic. These grades are cheaper and more susceptible to rust and corrosion. Yes, stainless steel can rust. While strong and corrosion resistant, 430 Grade stainless doesn’t contain Nickel in the alloy, which means that under certain conditions it will have both rust and corrosion.

Some Pellet Grills that use 430 Grade Stainless:

304 Grade Stainless

While more common in high-end gas grills in the $2-5,000 range, 304 Grade stainless is less common in pellet grills. It is commonly used in cookware, appliances, and sinks, however. It is considered a more “outdoor” grade of stainless, as well as a more attractive grade. The most important characteristic of 304 Grade (also called 18/8 Stainless, referring to its 18% Chromium and 8% Nickel composition) is that is superior in heat, corrosion, and rust resistance due to its Nickel content (which also makes it more expensive.) It is also a little less difficult to machine form than 430 Grade, also adding to its cost.

Some Pellet Grills that use 304 Grade Stainless:

- RecTec

- Memphis Grills

- MAK Grills

316 Grade Stainless

Another Austenitic family grade is 316 Stainless. It is much less common in pellet grill manufacturing. We know of no one currently using it in their pellet grills. The main difference in 316 Grade and 304 Grade, as you can see in the illustration above, is that it is considered “marine grade” due to Molybdenum added to the alloy. It is used in highly corrosive industrial environments and in the marine industry. There are a few grill makers using 316 Grade, however.

Some Pellet Grills that use 304 Grade Stainless:

- Solaire (gas)

- Blaze Grills (gas)

As a useful summation of the differences, here’s a quote from a large stainless steel distributor’s product information:

Grade 430 has 16% of chromium, and is mostly used indoors. Grade 304 has 18% of chromium, which makes it suitable for general purposes, including outdoor exposures. And in marine environments you need Grade 316, which has 16% chromium and also 2% of molybdenum to help it resist the attack of salt. 316 is known as marine grade.

—STAINLESS STEEL MAGNETISM & CORROSION RESISTANCE; AUSTRAL WRIGHT METALS

Steel Gauge: Thickness Matters

Along with stainless family and grade, the last characteristic to consider is a steel’s gauge. Gauge is simply a measure of thickness. Simply put, the lower the gauge, the thicker the metal. To illustrate this point, while 20 gauge (0.038” thick) is a common stainless steel gauge on say a grill lid, some manufacturers may use 18 gauge, which is even thicker, at 0.05” thick. The chart below offers a comparison of gauges, with a US quarter and dime shown for comparison.

Stainless Steel Gauge Chart

| Gauge Number | Inches | MM |

| 8 | .17187 | 4.365 |

| 9 | .15625 | 3.968 |

| 10 | .14062 | 3.571 |

| 11 | .125 | 3.175 |

| 12 | .10937 | 2.778 |

| 14 | .07812 | 1.984 |

| US Quarter (coin) | .069 | 1.750 |

| 16 | .0625 | 1.587 |

| US Dime (coin) | .053 | 1.35 |

| 18 | .050 | 1.270 |

| 20 | .0375 | .9525 |

| 22 | .03125 | .7937 |

| 24 | .025 | .635 |

| 26 | .01875 | .476 |

| 28 | .01562 | .396 |

| 30 | .0125 | .3175 |

Thicker gauges require more stainless steel, which can raise the cost to manufacture, but which also raises the resistance to corrosion. A thicker gauge will, however, be more resistant to corrosion and will last longer. If two pellet grills are similarly priced, the grill with the thicker steel, especially in critical components like the drip pan, the grates, the firepot, will be a better deal.

An excellent clue as to the gauge of steel overall (and a grill’s overall ability to last) is to look at the final weight of a grill, which we provide in our reviews. A similarly sized grill that weighs more is most likely using a lower gauge–and thus thicker–steel.

The (sort of) Myth of Magnetism

You may have heard the advice to take a magnet with you to shop for grills in person. Supposedly, you can quickly tell if a grill’s lid, its drip pan, its heat shield, etc. are constructed with higher-grade 304 stainless, or lower grade 430 stainless or carbon steel.

While it is true that 304 Grade (because it is Austenitic) is non-magnetic, it is non-magnetic only at its raw, unworked state. Once 304 Grade is “worked,” meaning when the metal sheets are bent, drawn, or formed into tubes, it becomes magnetic. The same is true for 304 Grade bolts and screws–hardware is often magnetic, even if it is 304 Grade. So the magnet test works, to a degree. You may notice a weaker magnetic pull with 430 than with carbon steel. And you may notice even less pull, perhaps none at all, with a magnet applied to 304 Grade. Unfortunately though, without a manufacturer fully disclosing the specific makeup of their pellet grill’s components, you can’t really know for sure.